The combination of nylon in the warp and weft is known as a nylon belt, and it is frequently used in multi-ply conveyor belts for the transportation of lumpy or bulky items. Nylon’s primary drawback is that it must absorb up to 10% of its weight in water, making it unsuitable for usage in wet situations because the belt’s dimensions will change. It does have certain advantageous qualities, though, like brilliant fatigue, impact and mildew resistance, good abrasion resistance, and strength. Read More…

Our conveyor belts are ISO 9002 and FDA certified. We can use our belts in nearly every industry, from transmission timing belts to conveyor belts for foods.

Creating conveyor belts at Fabrication Unlimited such as rubber belting, flat belts, endless belting, PVC, urethane belting, timing belts, cleated belting, specialty unscrambler belts (made-to-order), & corrugators belts, can be done with fast turn around for all fabricated belting offered. Serving food processing, agricultural, pharmaceutical, recycling, beverage and other industries.

Custom conveyor belting is fabricated by Beltservice Corporation and available through our distributors or OEMs. From this conveyor belt manufacturer, you will find agricultural, cleated, elevator, food handling, heat-resistant, heavy-duty and light-duty, incline, package-handling belting and more.

Come to Con-Belt Inc. for quality flat belts. Established in 1991, we have over twenty years of manufacturing experience and can meet your specifications and exceed your expectations. All of our products are made with pride in U.S. and are compatible and interchangeable with most major manufacturers’ conveyor equipment. Contact us today for further information about the products we offer.

More Nylon Belt Manufacturers

In material handling systems, conveyor belts move products or processed materials that can be light or heavy, abrasive, heated or frozen, very lumpy, or complex powder or granular products of different shapes and sizes.

Parts of a Nylon Belt

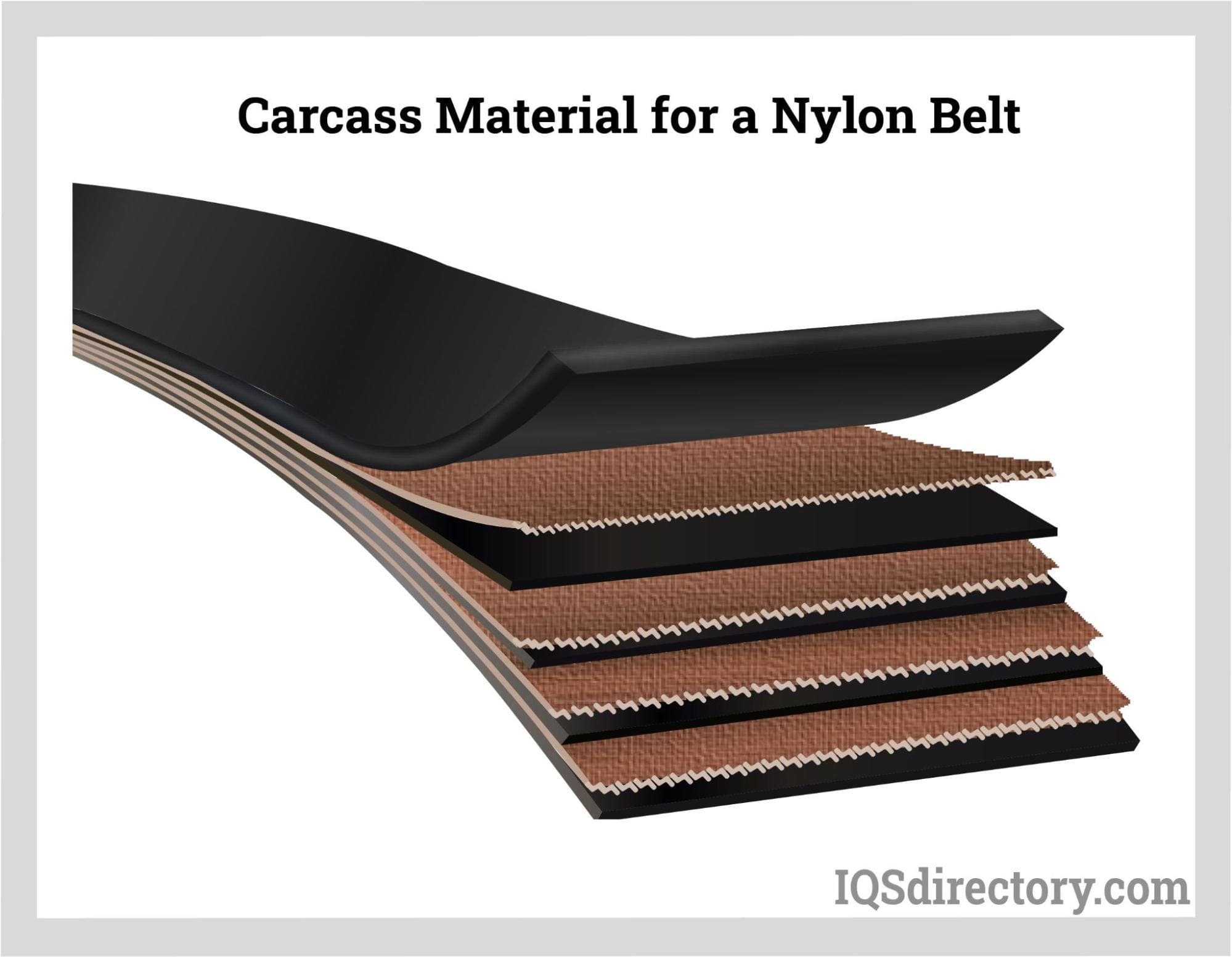

The majority of conveyor belts are made up of two parts:

- The Carcass, or Canvas

Both the warp and weft of nylon canvas are made of nylon strands. There are two types of nylon canvas: "nylon 6" and "nylon 66." The physical characteristics of nylon 66 are identical to those of nylon 6; however, it is more heat resistant and has a higher melting point. As a result, high-performance, high-quality, heat-resistant conveyor belts are made of nylon 66 canvas. Contrarily, nylon 6 is inexpensive and aids in lowering the cost of conveyor belt production. In addition, the plied woven nylon fabric used to create the nylon canvas gives it enough strength to withstand the operating tensions and support the weight.

- Covers

In conveyor belt structures, rubber covers are used to protect the base conveyor belt carcass and, if possible, to lengthen its useful life. Additionally, covers do give the finished belt several desirable qualities, such as the following:

- textures

- to make the belt more inclined

- to regulate a product's cleanability

- resisting cuts

- improved resilience to the impact

- resistance to wear

- resistance to fire

- resistance to the usage of chemicals and oil

The rubber cover's type, quality, and thickness are chosen based on the belt's expected service life. The material carried by the belt and the environment it will function in dictate the precise cover formulation employed in each belt construction. Modern belt constructions are significantly less vulnerable to moisture and chemical assault and do not require edge protection due to their high adhesion levels and synthetic carcasses. The slit-edge belt distribution programs currently employed in the belting industry are made possible by them.

Manufacturing Process of Nylon Belts

Receiving & Twisting Yarn

Receiving and twisting the yarn together is one of the initial steps in the production process. First, single yarn strands are twisted together, making a thread. The thread is then twisted into a spindle, where it is stored.

Weaving

The next step is feeding the frayed yarn threads through the loom, which gathers them together and forms the fabric belt's shape and body.

Numerous weaving techniques result in layers of material that have weight. Which approach will be used depends on the working circumstances. The three common weaving styles for conveyor belts—plain, twill, and basket weaving—are listed below.

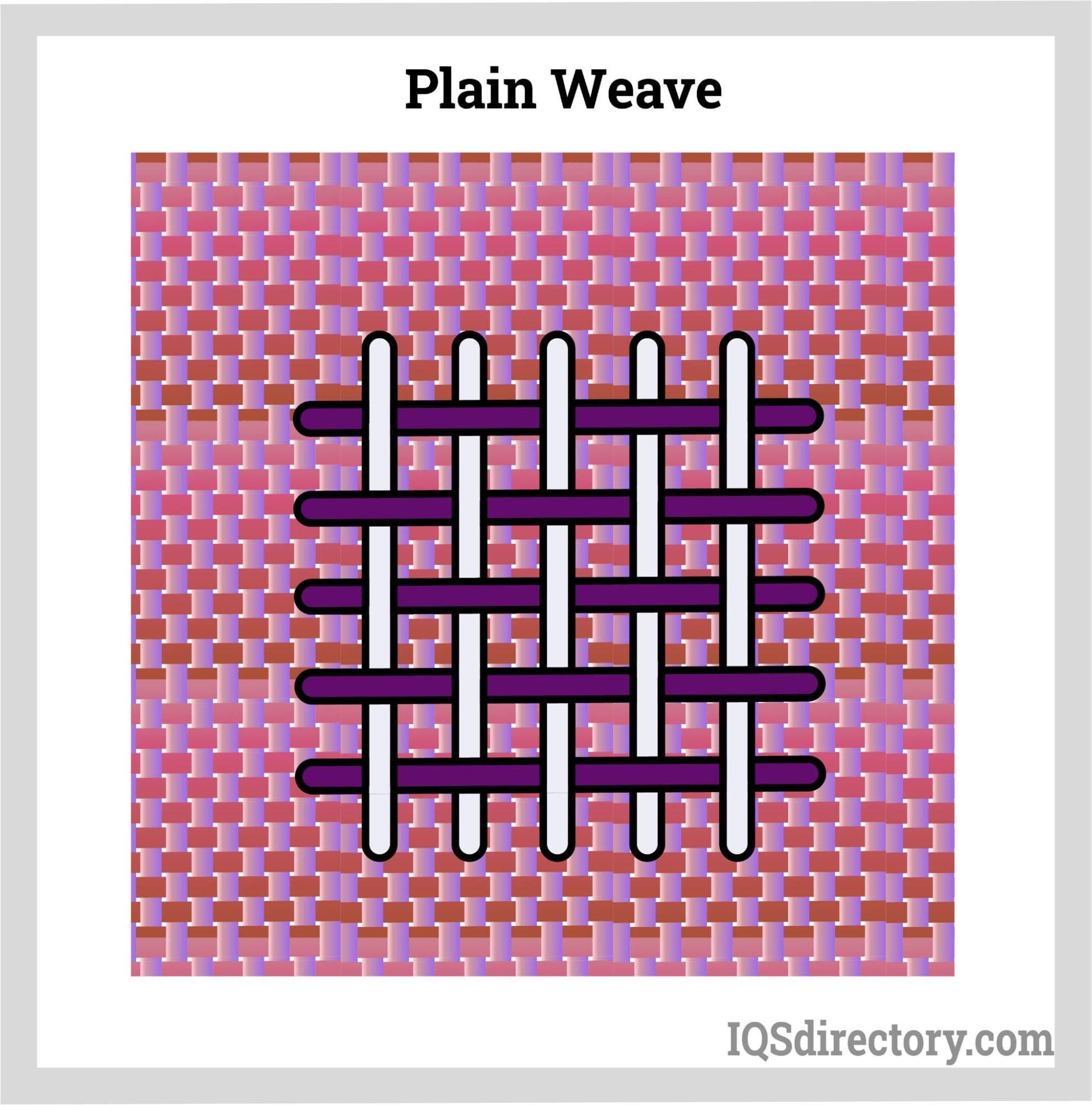

Plain Weaving

Plain weaving is the most popular method for creating a load-bearing textile layer for conveyors with flat belts. Warp and weft yarns are entangled in plain weaving, one below the other. However, the excessive degree of wrinkling in this weaving renders the mechanical characteristics worse than in other types. As a result, lesser-load conveyor belts use it.

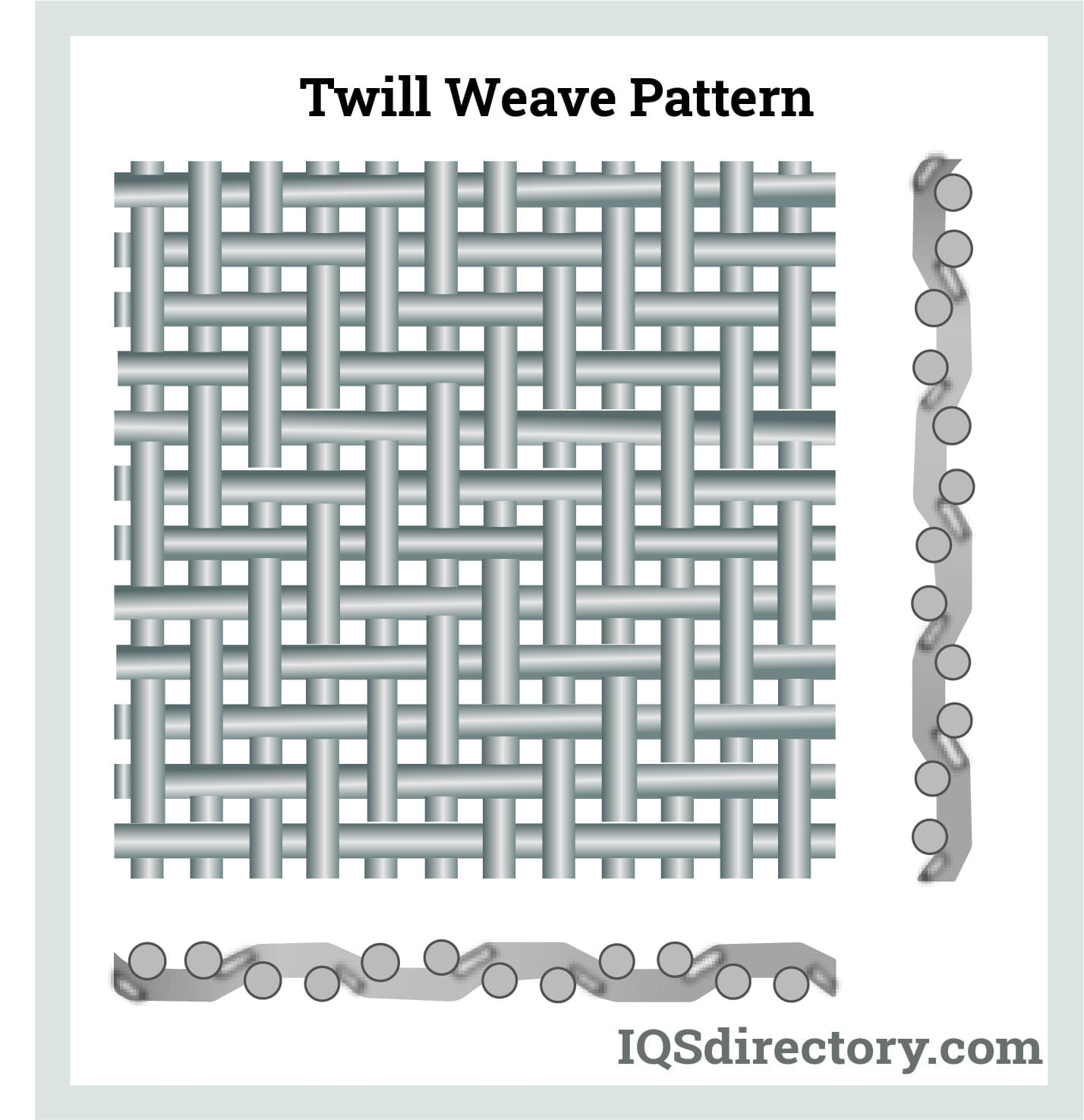

Twill Weaving

Twill and basket weaving are used to get higher mechanical qualities than plain weaving. In twill weaving, two or more weft yarns alternate with the warp threads in a recurring pattern. Twill weaving results in diagonal lines on the fabric layer's face. All the warp yarns are interwoven in the same manner to create these lines, with each warp yarn's interweaving points being moved by one peak of the weft about the warp yarn before it.

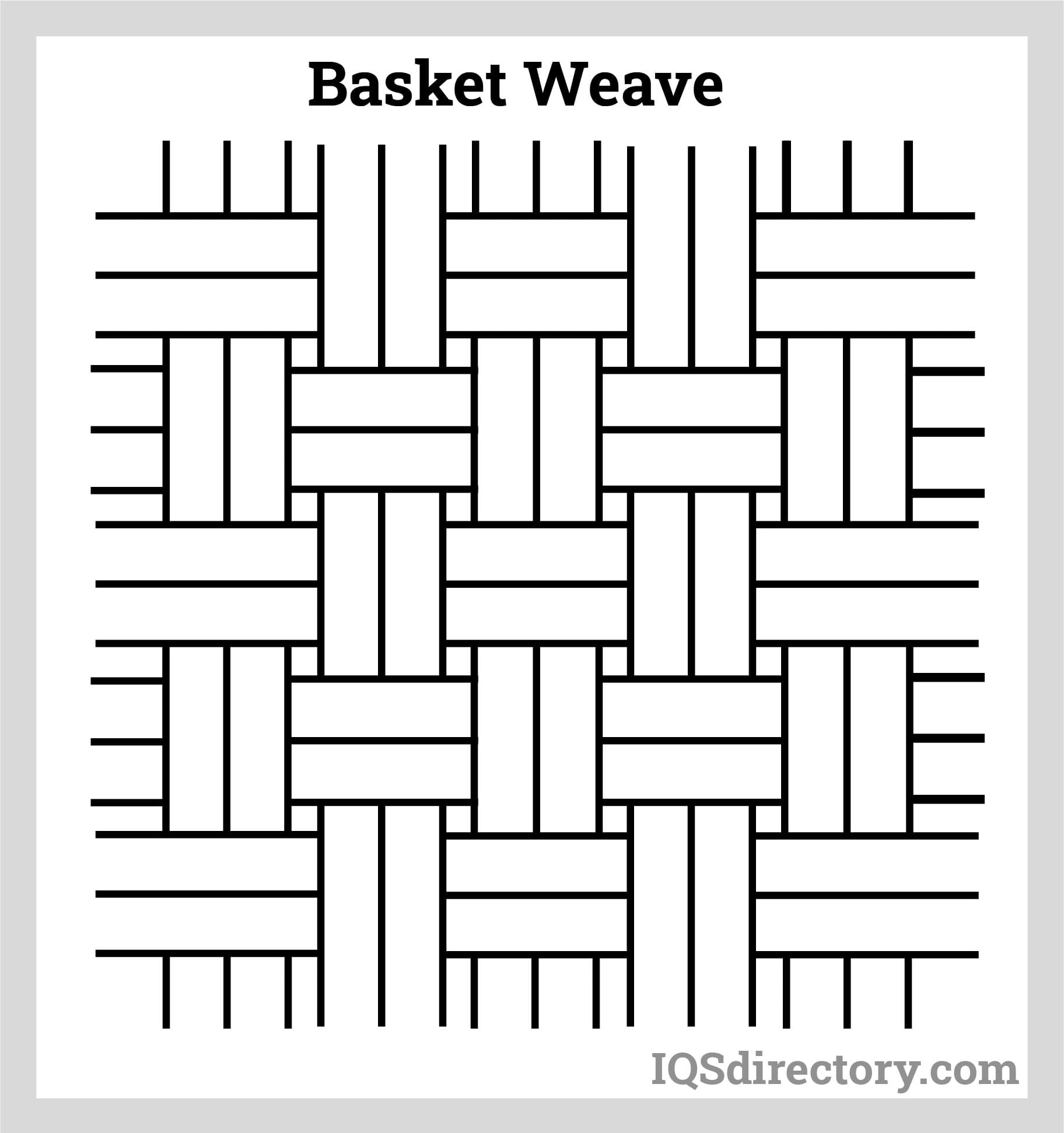

Basket Weaving

In this technique, the main difference between basket weaving and plain weaving is that two or more warp yarns alternate with two or more weft yarns. As a result, this style of weaving has less fiber crease than plain weaving, which improves the qualities of the textile layer.

Treating

In this stage, the fabric is treated with a specifically designed and unique adhesive. Next, heat is delivered through a computerized system to fuse the thread and rubber parts to form a rubber belt.

Calendaring

The rubber compounds are disintegrated in the following stage, known as calendaring, which is done to apply the fabric carcass.

Laminating

The laminating procedure involves building the conveyor belt. The fabric carcasses that have been calendared are then run through a laminating table. Pushing the calendared heaps together creates a conveyor belt.

Applications of Nylon Belts

- Belts for processing food and beverages are intended for food and beverage applications.

- Conveyor belts for forests: These are made for logging, sawmill, tree farming, and similar businesses.

- Belts for mining and quarrying are used to move materials like ore, stone, tailings, gravel, and aggregate.

- Belting for agriculture: This is used for silage transfer and belts for farm machinery.

- High-temperature belting: These are utilized with materials that can withstand high temperatures without harm. They can move materials at a high temperature.

- Production lines in factories employ belting for fabrication and manufacturing.

- These abrasion-resistant belts are suitable for cardboard and packing paper in packaging processes.

Advantages of Nylon Belts

- Excellent strength

- Thin body with impact resistance

- High flexing performance

- Excellent troughability

- A long service life

Disadvantages of Nylon Belts

- Their simple design entails few features.

- The belt might be tough to clean.

- Sticky material may become trapped on the belt and transfer to the roll, idler, and pulley on the opposite side.

Choosing the Correct Nylon Belts Supplier

To make sure you have the most beneficial outcome when purchasing Nylon Belts from a Nylon Belts Manufacturer, it is important to compare at least 4 Manufacturers using our list of Nylon Belts suppliers. Each Nylon Belts Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Nylon Belts company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Nylon Belts businesses with the same quote.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches