Polyurethane belts can be used for a wide variety of applications including food conveyors, packaging equipment, dental drills, brake rollers, chemical mixers, computer printers, HVAC equipment and much more. Read More…

Our conveyor belts are ISO 9002 and FDA certified. We can use our belts in nearly every industry, from transmission timing belts to conveyor belts for foods.

Creating conveyor belts at Fabrication Unlimited such as rubber belting, flat belts, endless belting, PVC, urethane belting, timing belts, cleated belting, specialty unscrambler belts (made-to-order), & corrugators belts, can be done with fast turn around for all fabricated belting offered. Serving food processing, agricultural, pharmaceutical, recycling, beverage and other industries.

Custom conveyor belting is fabricated by Beltservice Corporation and available through our distributors or OEMs. From this conveyor belt manufacturer, you will find agricultural, cleated, elevator, food handling, heat-resistant, heavy-duty and light-duty, incline, package-handling belting and more.

Come to Con-Belt Inc. for quality flat belts. Established in 1991, we have over twenty years of manufacturing experience and can meet your specifications and exceed your expectations. All of our products are made with pride in U.S. and are compatible and interchangeable with most major manufacturers’ conveyor equipment. Contact us today for further information about the products we offer.

More Urethane Belting Manufacturers

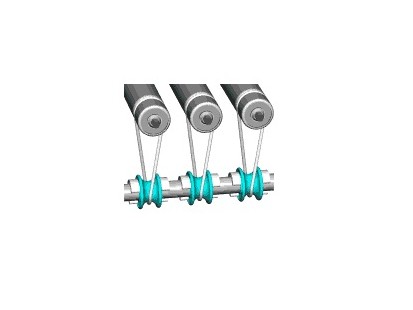

Polyurethane and urethane are two different substances; urethane is another word for ethyl carbamate, which is not a component of polyurethane and is chemically distinct from it. Despite this distinction, the words "urethane" and "polyurethane" are often used interchangeably. Polyurethane belts are used as power transmission belts and as conveyor belts in comparatively light-duty applications.

Temperature has a definite effect on the resiliency of polyurethane belts. Polyurethane's physical resilience diminishes at higher temperatures. This means that a polyurethane belt's resiliency at 120°F (49°C) decreases to roughly 70% of its resiliency at room temperature, it and drops to about 10% at 150°F (66°C). Also, as temperature decreases, polyurethane becomes more brittle. When polyurethane belts are left overnight in low temperatures, they can take a set that can cause welds to shear apart.

Cleaning polyurethane belts with Oxine (Chlorine Dioxide) or isopropyl alcohol (rubbing alcohol) is acceptable without prolonged exposure or high concentrations, which can damage the polyurethane. Polyurethane belts may also be washed in lukewarm water with regular liquid dishwashing soap.

Frequent washing is not recommended for more hygroscopic polyurethane belts as it can cause damage over time, especially with hot water temperatures. Polyurethane belts should not be sanitized with bleach because it causes them to crack and lose elasticity. Polyurethane belts can be formed into almost any required shape; this is one of the primary benefits of manufacturing polyurethane belts.

Polyurethane is just one of many synthetic polymer materials that are used for the construction of belts. Natural rubber as well as synthetic rubber materials like neoprene and silicone are also widely used. Correctly pairing a polyurethane belt with its application will ensure the longevity of the belt and the effectiveness of the process in which it is involved.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches