V-belts efficiently transfer mechanical power between various machine components. They are frequently used in automotive engines to power accessories like fans, alternators, and steering pumps. V-belts have a V- shaped trapezoidal cross-section and can be classified into different varieties based on their dimensions. V-belts provide excellent traction, speed transfer, load distribution, and a prolonged service life. Read More…

Our conveyor belts are ISO 9002 and FDA certified. We can use our belts in nearly every industry, from transmission timing belts to conveyor belts for foods.

Creating conveyor belts at Fabrication Unlimited such as rubber belting, flat belts, endless belting, PVC, urethane belting, timing belts, cleated belting, specialty unscrambler belts (made-to-order), & corrugators belts, can be done with fast turn around for all fabricated belting offered. Serving food processing, agricultural, pharmaceutical, recycling, beverage and other industries.

Custom conveyor belting is fabricated by Beltservice Corporation and available through our distributors or OEMs. From this conveyor belt manufacturer, you will find agricultural, cleated, elevator, food handling, heat-resistant, heavy-duty and light-duty, incline, package-handling belting and more.

Come to Con-Belt Inc. for quality flat belts. Established in 1991, we have over twenty years of manufacturing experience and can meet your specifications and exceed your expectations. All of our products are made with pride in U.S. and are compatible and interchangeable with most major manufacturers’ conveyor equipment. Contact us today for further information about the products we offer.

More V Belt Manufacturers

Types of V-Belts

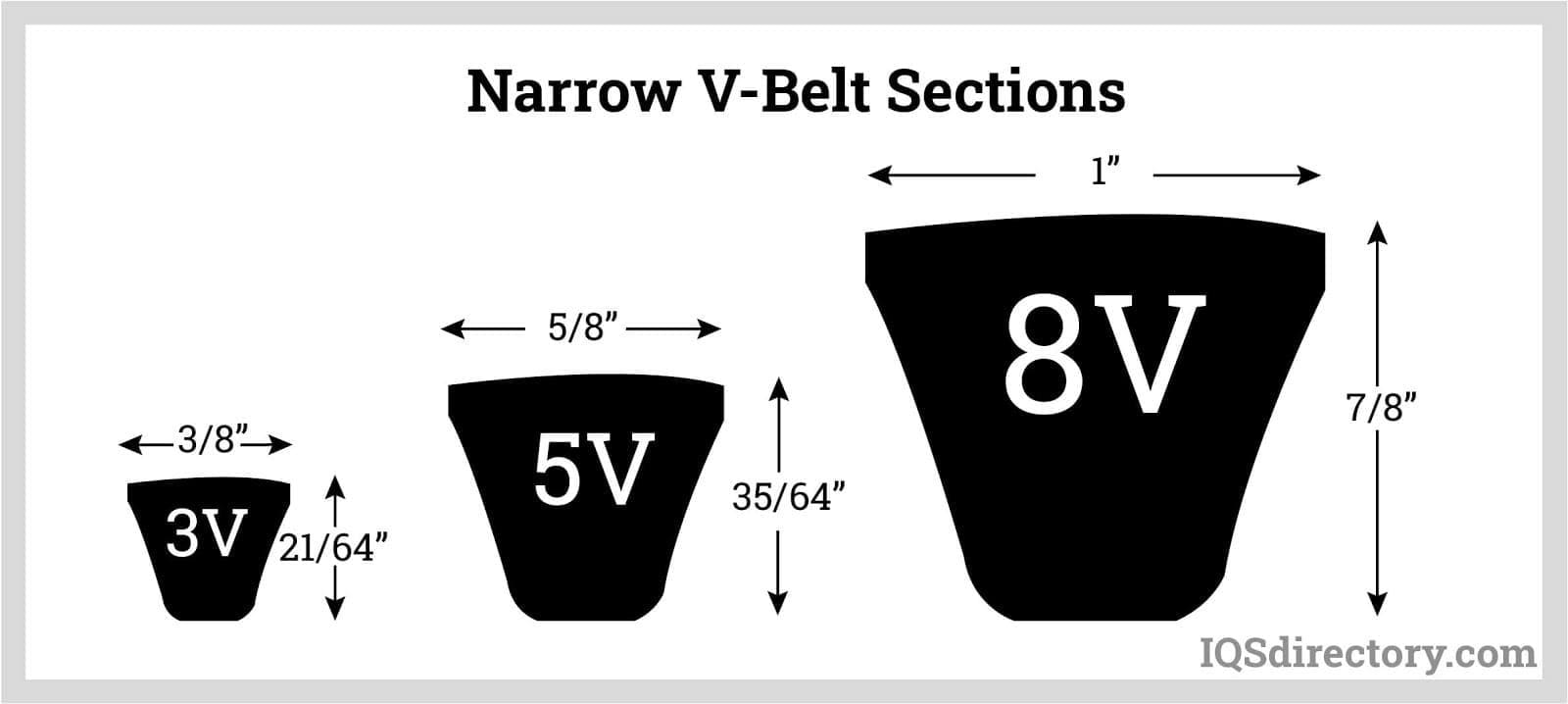

Narrow V-Belts

Narrow V-belts are used to transmit heavier loads through their more compact shape than standard V-belts. The terms 3V, 5V, and 8V are terms to classify narrow V-belts; these classifications are explained in the image below. These standards, however, are utilized mostly in North America to classify a belt’s profile. Elsewhere, narrow V-belts are classified under the metric system.

The American 3V listing roughly corresponds as SPZ and the 5V-belt as SPB in the metric classification system. SPB is a single, metric V-belt with a 13mm nominal thickness and a 16mm nominal top width. SPZ is a metric V-belt with a nominal thickness of 8mm and a top width of 10mm. However, these translations are not exact and using SPZ and SPB pulleys with American-standardized pulley systems is not advised.

Standard V-Belts

Standard V-belts are the earliest kind of V-belts widely used in power transmission. They are sometimes referred to as classical or conventional V-belts. Standard V-belts come in various sizes, denoted by the letters A, B, C, Y, Z, D, and E. When employing DIN standards, their designation is indicated by numerals that are the same as the millimeter value of the belt's top width.

All sizes feature a top width-to-height ratio of 1.6:1 and a 40° included angle. A DIN standard is a specification created at the German Institute for Standardization (DIN) in Berlin that establishes uniform standards for goods and services, including quality, minimal functionality, features, and measurements.

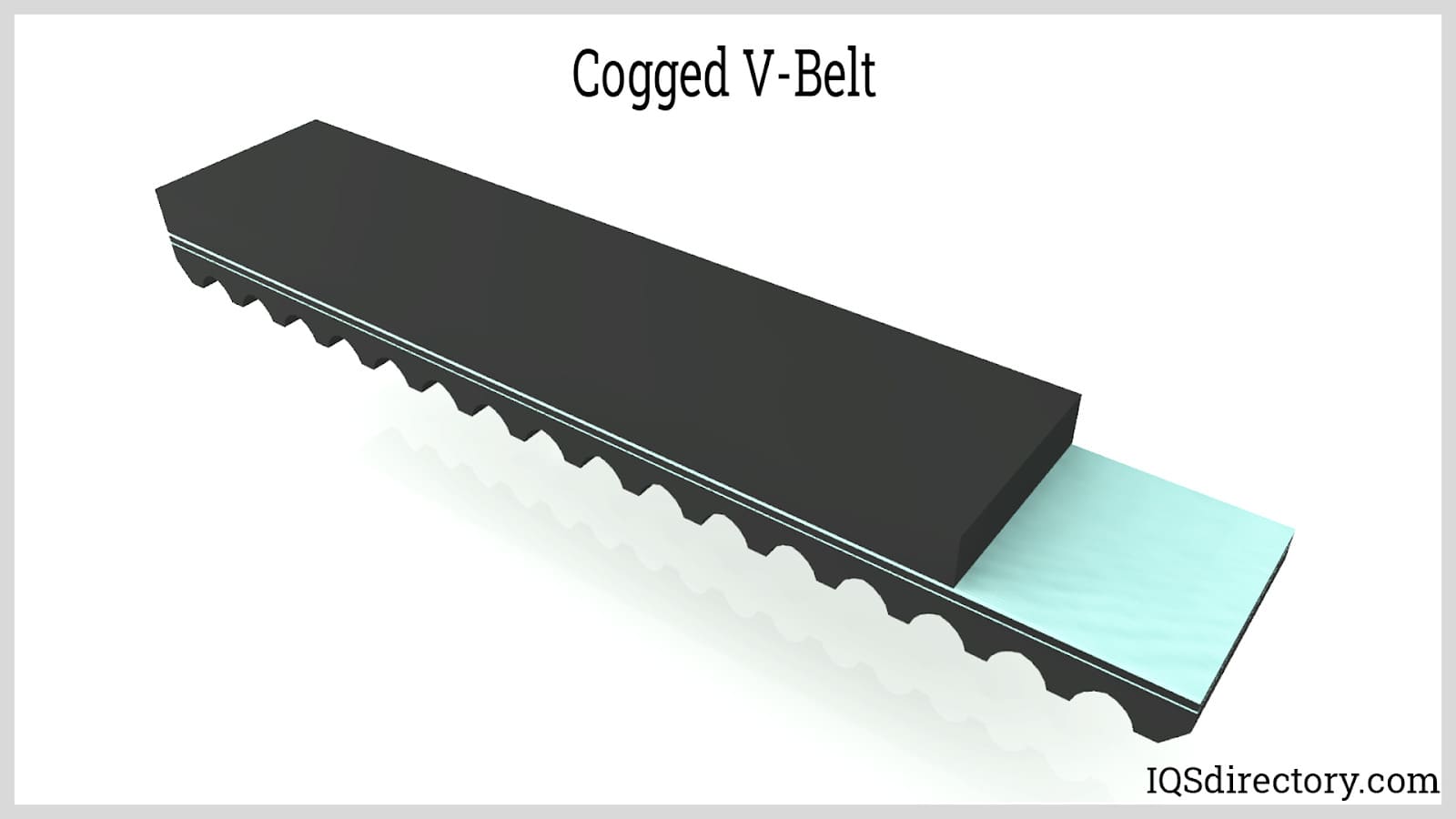

Cogged V-Belts

Cogged V-belts may be bent at a smaller radius because they feature cogs or notches on the bottom. Different from the earlier varieties, they are only partially covered in fiber. The cross-sectional dimension of traditional, wedge, narrow, banded, and fractional horsepower V-belts can be adopted by cogged belts.

Variable-Speed V-Belts

A variable-speed V-belt has a broader cross-section than traditional belts with a raw edge cogged design. They are made to be utilized with pulleys that have varying speeds. They can create their segment in normal or non-standard sizes. Variable-speed belt designations differ between manufacturers. Typically, they are constructed of EPDM rubbers (ethylidene norbornene, dicyclopentadiene, and vinyl norbornene are the dienes used to make EPDM rubbers) or chloroprene rubber (neoprene).

Double-Cogged V-Belts

The idea of the double-cogged V-belt is an offshoot of the cogged V-belt design design. They are utilized when a tight pulley radius and high belt flexibility are necessary. The belt can be bent in a serpentine pattern thanks to the cogged design on the top side. This is employed to power numerous pulleys. Manufacturer standards determine the dimensions of double-cogged V-belts.

Banded V-Belts

A banded V-belt comprises many V-belts connected in parallel by a band or cover made of cloth on the top side. Each V-section can have individual belts with traditional, wedge, or thin proportions. Banded V-belts are typically used for high-power applications.

Agricultural V-Belts

Agricultural V-belts are wrapped and made to withstand more-severe abrasion from materials like dust, sand, and grains. These belts are also exposed to rain and sunlight, which readily deteriorate common rubber compounds. These factors led to development of more robust polyurethane blends for the elastomer core and Kevlar® fibers for the tension cords in agricultural V-belts. In addition, some manufacturers combine traditional, narrow, double, and banded section V-belts for their specifications.

Fractional Horsepower V-Belts

V-belts with fractional horsepower are appropriate for light-duty applications. For instance, tools in a machine shop or typical home appliances generally read as 2L, 3L, 4L, or 5L. The number before the L represents the belt's upper width times 1/8 of an inch (3.2 mm).

Advantages of V-Belts

- The V-belt and pulley almost slip together.

- A pulley system driven by a V-belt runs quietly.

- Their compact structure results in higher speed transfer.

- A system of V-belt pulleys reduces vibration.

- Their excellent grip is provided by V-grooves, making high-power transmission possible.

Disadvantages of V-Belts

- Compared to flat-belt pulley systems, V-belt pulley construction is challenging.

- Due to centrifugal tension, V-belts cannot be used at speeds below 5 meters per second and beyond 50 meters per second.

- V-belt drives cannot be employed over long distances because of their comparatively high weight per unit of length.

Choosing the Proper V-Belt Manufacturer

To make sure you have the most beneficial outcome when purchasing V-Belts from a V-Belt Supplier, it is important to compare at least 5 or 6 Companies using our V-Belt directory. Each V-Belt Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each V-Belt business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple V-Belt companies with the same quote.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches