Conveyor belts are flexible pieces of material used to move items along a conveying system. Note that conveyor belts are not the same thing as machine belts. The primary difference between conveyor belts and machine belts is that machine belts are used to transmit energy while conveyor belts are used to transport goods. They are also not to be confused with warm conveyor belts and cold conveyor belts, which are meteorology terms. Read More…

Our conveyor belts are ISO 9002 and FDA certified. We can use our belts in nearly every industry, from transmission timing belts to conveyor belts for foods.

At Forbo Siegling, our conveyor belts can be found in a variety of industries and applications, such as conveyor and processing belts in the food industry, treadmills in fitness studios, and flat belts in letter sorting systems. We are a leading manufacturer in our industry, and leading companies all over the world partner with us in developing groundbreaking solutions.

Megadyne started manufacturing transmission belts in 1957. Continual new product research and development continues to make Megadyne a world leader. Our product line includes polyurethane and rubber belts which are used in virtually all industrial drive applications for power transmission, synchronization/timing, conveying and linear positioning. Call us today!

Sparks Belting designs, manufactures and distributes customized conveyor belting, motorized pulleys and powered rollers. We have a belting assortment of over 200+ styles that include: polyurethane, modular, endless, v-guide, lacing, cleat and so many more. Sparks can provide you with innovative solutions for your conveyor belting and pulley requirements. Contact us today.

More Conveyor Belt Manufacturers

Conveyor Belting Applications

Conveyor belt systems are essential for continuous transport of items from one area to another in many commercial and industrial facilities. There, they can help to significantly reduce production times and reduce overall labor costs. Factory assembly lines, for example, always use conveyor belts to help make the process more efficient. Even small retail stores have conveyor belts at their checkouts to keep goods moving before and after they have been scanned. In fact, almost every industry makes use of conveyor belting.

Conveyor systems are mechanical devices or assemblies that move goods, products, and other materials from one place to another. They are useful in transporting heavy goods, mass-produced products, and potentially harmful objects. Industries like automotive, mining, electronics, food processing, textile, packaging, and many others make great use of these systems to handle their materials and goods.

Conveyor Belts are material handling systems that transport products or materials using continuous belts. Between two end-pulleys, the belt is expanded in an unending loop. Rubber, fabric, leather, plastic, and metal are common conveyor belting materials. A thicker and stronger conveyor belt material is required to transport larger loads. Conveyor belts are usually powered and can run at a variety of speeds depending on the amount of material that has to be moved. For bulk or heavy items, troughed belt conveyors can be used. Steel conveyor belts are the most durable and are suitable for big loads and other difficult bulk handling jobs.

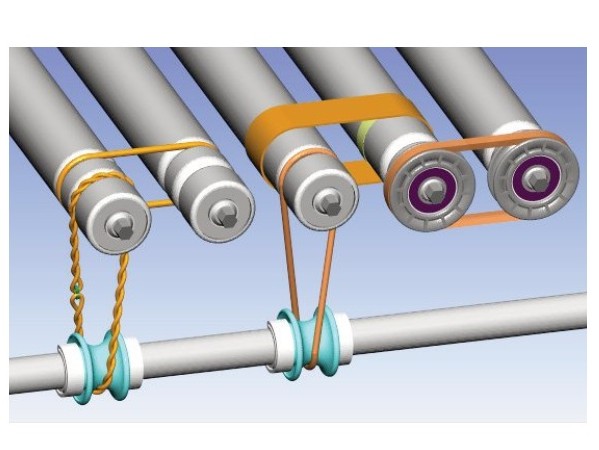

Belt conveyors, more commonly known as conveyor belts, are one of the simplest conveyor types. The system runs using a motor and pulley combination that rotates an attached belt into a loop using rollers. This simple and easy-to-use equipment has two applications: general material handling, such as moving packages inside a factory, and bulk material handling, such as transporting large volumes of resources like grain, salt, gravel, coal, and more.

High productivity is important in conveyor belt systems. Downtime caused by time spent repairing the system should always be prevented to avoid financial loss. A conveyor belt splice is an important component of a belt system’s efficiency.

Conveyor belts are one of the most crucial parts of a food processing line, as they can have a big impact on the quality and safety of the items they convey. Depending on the purpose, there are many different varieties of conveyor belts. For primary and secondary food processing, Plastic Modular, Solid Flat Belt, and Wire Mesh are among the most important considerations.

Some examples of these industries include food and beverage processing, pharmaceuticals, waste management, milling, mail sorting, and printing. Conveyor belting is also common in several types of engines. Without conveyor technology, facilities in these and other industries would never be able to operate as efficiently as they do. Manual labor would be required to move and sort goods, which would be very time consuming.

History of Conveyor Belting

Manufacturers first began using conveyor belt systems at the tail-end of the 1700s. The first one that we know of was introduced to the world in 1795. It was made up of a wooden slider bed, a leather conveying belt, pulleys, and a hand crank. Seamen and merchants used it to load products and goods onto ships. Soon afterwards, in 1804, the British Navy commissioned the invention of a steam powered conveyor, with which their cooks could efficiently make biscuits.

After this, the use of conveyors lapsed for some time. It picked up again in the late 1800s, spurred on by the requirements of miners and the burgeoning automotive industry. First, in 1892, American inventor Thomas Robins designed a conveyor belt at the behest of Thomas Edison. Edison wished to have an efficient way to cart coal and ore from the coal mines run by his company, Edison Ore-Milling Company. Robin’s solution was a leather belt with pieces sewn together with wire. His invention proved successful, and it took first prize at both the Saint Louis Exposition and Pan-American Exposition. It also took the grand prize at the 1900 Paris Exposition.

Next, in 1901, a Swedish company called Sandvik developed a steel conveyor with which they could convey gravel. In 1905, an Irish miner turned engineer named Richard Sutcliffe invented the very first underground conveyor. This conveyor changed mining significantly, as it drastically cut down on the labor required to get materials from the mine to aboveground. Just three years later, engineers invented the roller conveyor.

In 1913, Henry Ford used the conveyor belt as the driving force of his automotive assembly line. By combining the assembly line with the conveyor belt, he showed the world how to make products manufacturing much faster and more standardized. Quickly, other manufacturers in other industries adapted his system for their purposes.

Little changed with conveyor belts for many years, until 1957, when B.F. Goodrich invented and patented a rubberized steel belt with a longer service life than any conveyor belt before it. It was set apart from others by taking a half twist that, by exposing both sides of the surface area, cut the exposure to each in half. Over time, as scientists created stronger materials, Goodrich engineers came up with even more durable belt products that did not require the twists.

An American company called Intralox patented the first plastic conveyor belts in 1970. Since then, many other companies have gotten in on the plastic belt. Today, conveyor belts are available in a wide range of rubber materials and polymer materials. They are capable of functioning in countless environments.

Conveyor Belt Design

Generally, conveyor belts are flat and made from an elastic material like rubber. To work, they are most often mounted on a series of rollers that are powered by an electric motor.

Materials

A typical flat belt has two or more layers for added durability and wear resistance. The core material is a fabric or wire mesh. Common examples include aramid fiber, polyester, cotton, steel, stainless steel, or galvanized steel.

This core is coated in layers on either side of the mesh. Manufacturers can make these layers using a variety of materials, as long as the chosen material is durable, strong, and capable of operating without interruption. The material may also either be flexible and completely seamless or made up of a series of hard but light pieces. Manufacturers most commonly select rubber as a belt material, but they often also choose a plastic like PVC, or polyurethane.

Design Considerations

When designing conveyor belts, manufacturers consider application factors such as the products or materials you wish to transport, the weight and shape of those objects, the length of your conveying system, the presence of any existing equipment into which you need to integrate your conveyor belt, the layout of your space, the environment of your space, how often you plan to run your conveyor belt and the standard requirements of your system (FDA, medical grade, food grade, etc.).

Based on these factors, manufacturers can make a lot of decisions, including materials, belt type, belt size, belt groove shapes and belt construction. For example, if a conveyor will exist in a space where it needs to work against gravity, manufacturers can design a belt with ridges in it to keep objects from rolling off while they are moving. Or, for heavy loads, they can design a wider belt.

Types of Conveyor Belts

Flat belts are linear belts that operate continuously. They are the most common type of conveyor belt. As such, they are used for a wide variety of applications, such as industrial coating, draining, heating, cooling, drying, mining, and logging.

Continuous belting is belting that has neither seams nor joints. For this reason, it is sometimes referred to as “endless belting”.

O-ring belts, also known as round belts or endless round belts, are stretchy belts with a few different applications. Often, customers use them to keep flat belts firmly on their rollers or connected to chains, instead of slipping inward during motion. This is mostly a risk at curves or turns in large conveyor systems. Also, customers frequently purchase o-ring belts for use in power transmission systems.

Cotton conveyor belts are lightweight, tightly woven belts made from cotton. They are best for use in food processing and baking. Manufacturers can design them to comply with FDA/USDA standards.

Timing belts are used in internal combustion engines and work in tandem with the engine’s gears and cogs. Many manufacturing facilities accept custom orders for belts that are being designed for a specific function or piece of equipment.

Fin belts are named for their fin-like components, which stick out from the main belt. These fins are made to flex and pick up quickly moving containers. These are used to separate cartons in packaging facilities. Flat belts are made of homogeneous thermoplastic. They are seamless and do not have hinge rods. Additionally, they have a reduced OSP (100 percent closed surface) to reduce bacterial harborage. These belts work best in raw and cooked meat applications, as well as fruit and vegetable processing lines.

Wire belts are not made with a rubber or polymer belt, but rather woven wire cords (usually steel or stainless steel cords) or chain mail-esque wire links. Wire belts are used for heavy duty applications. Wire Mesh belts are composed of stainless steel series 300 and have a non-exposed hinge mechanism to prevent bacterial harborage. Because of their superior heat resistance and belt stability, these belts are ideal for breaded products and are mostly utilized for cooked food.

V-belts are belts that feature a v-shaped groove and run in a pulley. They transit higher torque than flat belts but require less width and lower tension to do so. For added traction, manufacturers can deepen the V slot. V-belts are best with lightweight applications.

Rubber conveyor belts are all conveyor belts made from natural or synthetic rubber materials, such as urethane, silicone or neoprene. Rubber belts are as versatile as rubber itself, so they are available in a wide range of thicknesses and grades. They can be used for anything from food conveying to industrial conveying.

Roller conveyors are conveyor systems that run using a set of rollers installed inside a frame. In this case, the belt sits on top of the rollers. When the rollers rotate, the belt moves forward and takes the goods it is conveying with it.

Conveyor Belting Accessories

Conveyor belt accessories play vital roles in the efficient operation and maintenance of conveyor systems. One of the key accessories is conveyor belt fasteners, which are used to securely join the ends of a belt together, ensuring a strong and reliable connection that can withstand the demands of material handling. Another important accessory is belt lacing strips, which consist of flexible metal strips used to create a continuous loop by connecting the ends of a belt. Clipper lacing is an alternative option that utilizes individual metal clips inserted into the belt’s ends and secured with a lacing machine, providing a durable connection. Hooks are designed to attach to the conveyor belt and facilitate material handling, allowing the hanging of buckets or attaching other accessories to enhance the versatility of the system.

Plate grips are utilized to hold metal plates or cleats in place on the belt, preventing slippage and ensuring the smooth and efficient transportation of materials. Skirtboard and sealing systems, on the other hand, are essential accessories that help contain material spillage and minimize leakage at transfer points. Skirtboard, a rubber sheet installed along the sides of the conveyor belt, acts as a barrier to prevent material from escaping the system. Meanwhile, sealing systems, such as skirtboard seals and conveyor belt sealing systems, provide effective sealing solutions at critical points to reduce material leakage, enhance safety, and maintain a clean and controlled working environment.

Tracking systems are crucial for proper belt alignment and preventing belt misalignment. They include tracking rollers, guides, and sensors that ensure the belt stays centered on the conveyor and operates smoothly without rubbing against the framework, reducing wear and tear. Pulley lagging is another important accessory, which involves applying a layer of material, usually rubber, to the surface of a pulley. This improves traction between the pulley and the belt, preventing belt slippage and enhancing power transmission efficiency. Additionally, pulley lagging protects the pulley from wear, extending its lifespan and reducing maintenance requirements.

Belt cleaners are indispensable accessories used to maintain a clean and efficient conveyor belt system. They remove material residue and debris from the surface of the belt, preventing material carryback, reducing the risk of belt damage, and improving overall belt performance. Belt cleaners are available in various types, such as primary, secondary, and tertiary cleaners, each designed to address specific cleaning needs.

Determining the need for these accessories requires consideration of several factors. The type of conveyor belt being used is crucial in selecting compatible accessories. Factors such as the application, environment, material being transported, and maintenance requirements also play a significant role. For example, heavy-duty applications may require stronger and more durable accessories, while belts carrying abrasive materials may necessitate accessories that can withstand wear and tear. Proper installation tools, such as lacing machines or tools for attaching hooks, are also essential for efficient installation and maintenance.

By considering these factors and understanding the specific requirements of the conveyor belt system, one can determine the necessary accessories for optimal performance, longevity, and safety. Selecting the right accessories ensures a well-equipped conveyor system that can handle the demands of the intended application while minimizing downtime and maintenance efforts.

Proper Care for Conveyor Belts

The first step in caring for your conveyor belt has to do with how you use it. Basically, only use your conveyor belt within its designed limits. Do not put loads on it that exceed its weight capacity, and do not place substances on it that are not compatible with your belt material.

In addition to this, you need to regularly inspect your belt, keeping an eye out for contaminants like dirt and dust, as well as wearing and tearing and improper belting adjustment. Belting that is out of alignment is at risk of ripping, twisting and slipping. If you allow it to move loads while misaligned, your belting can easily become loose or stretched. This will lead to diminished quality, inefficiency, and risk of accidents and injury. You also need to make sure your belt is properly tensioned.

Proper lubrication is another way to make sure your conveyor belt works well and lasts for a long time. Lubrication will not only keep its constantly moving parts from abrading but will also stop contaminants from getting too close to their surfaces. Still, contaminants can be disruptive even if they don’t make it onto the surface of the conveyor parts. So, we recommend you also employ an air quality maintenance system or a dust collection system.

Conveyor Belting Standards

The quality standards to which your conveyor belts must adhere depend on your application, industry, and location. For example, if you are conveying food, your conveyor belt must be food-grade/FDA compliant. Likewise, if you are transporting agricultural material, your belt must be USDA compliant. To find out the standards you need to request for your particular belting, talk to your industry leaders.

Things to Consider About Conveyor Belting

There are many manufacturers out there that offer custom conveyor belts and standard conveyor belts, as well as discounted surplus conveyor belts, and used conveyor belts. What option is best for you depends entirely on your application and budget. To help you along the way, we’ve listed several high-quality conveyor belt manufacturers and suppliers on this page. Find out what they offer by browsing their profiles and/or websites.

Conveyor Belt Splices- Conveyor belt splicing is the joining of two conveyor belt pieces to either elongate or repair tears in a belt. There are many types of splices; the choice of which to use depends on the type of belt, its speed, and the type of material it carries. Having the proper, high-quality splice for your system can keep you from financial loss due to repairs.

Mechanical Splicing- A mechanical splicing system utilizes metal fasteners, hinges, or plates to make reliable joints between belts. This method can be applied to most types of belt systems and in many environments, making it a popular choice for industries like mining and quarrying. Here are some important considerations when deciding to use this option:

- Mechanical splices are easy to install. Depending on belt width and thickness, an installation crew could put on the splices in less than an hour with portable tools.

- The installation of mechanical splices is not affected by temperature, moisture, or contaminants.

- This splicing method offers reduced belt waste, and its visibility on the belt allows for easier inspection.

- Since material wear can easily be spotted, preventive maintenance can be performed earlier, reducing the risk of breakdown during crucial operations.

Vulcanized Splicing- Also called chemical splicing, this complex procedure makes use of heat and/or chemicals to attach belts for elongation or repair. This method requires specialized expertise and equipment to perform. Environmental factors like temperature and moisture also need to be taken into consideration. Though this process is demanding and expensive, vulcanized splices are usually smoother and more durable than mechanical splices. The two types of vulcanization are hot and cold.

- Hot vulcanization uses heat and pressure via a vulcanizing press. Though it is a time-consuming process, sometimes taking several hours, it creates stronger, longer-lasting splices than other methods.

- Cold vulcanization is a reliable technique that utilizes chemicals to attach two belt pieces. This method requires specific hand tools and high-quality bonding agents.

Conveyor belts will always be a top consideration in bulk materials handling. The system’s ability to safely handle large amounts of material in an orderly and timely manner makes it an indispensable asset of industrial production. Make sure that parts of your conveyor, like its splices, belt, motor, pulleys, and its metal or rubber-based rollers are made with high-quality materials.

To focus your search, we recommend you take some time to jot down your specifications, requirements, and questions. Don’t forget to include things like your budget, your quality standard requirements, your delivery deadline, and your support preferences (installation assistance, parts replacement, etc.). Once you’ve got your list together, get to looking. All of those manufacturers we’ve listed are experienced and trustworthy, but only one will be right for you. Find out which one that is by picking out three or four and reach out to each of them with your list. After you’ve spoken to each of them at length, compare and contrast their services and offers, and select the one that suits you best.

Choosing the Right Conveyor Belt Supplier

To ensure you have the most productive outcome when purchasing a conveyor belt or conveyor belt accessories from a conveyor belt supplier, it is important to compare several suppliers using our directory of conveyor belt suppliers. There, each conveyor belt supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each conveyor belt business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple conveyor belt-related businesses with the same form.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches